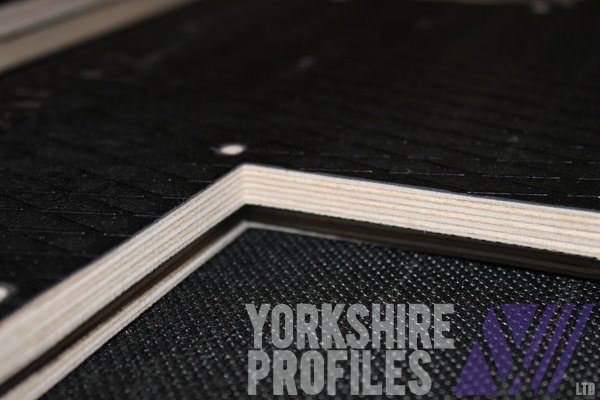

It isn’t always metals we handle here. Often we are required to cut a variety of materials which other cutting machines struggle to provide a high quality finish. These cut-outs were added to some composite plywood panels.

Extra details added into plywood panels on the waterjet cutting machine.

Waterjet cut composite plywood leaves a nice smooth finish.

The waterjet leaves a nice clean finish, unlike our laser cutter which would have left a distinctive burnt edge. The only down-side to waterjet cutting materials like plywood, is that on small holes, the pierce can lead to a small fracture as shown below.

Composite plywood material can fracture when piercing small holes.