Our latest investment has now been installed and will begin to benefit our clients immediately. The “NitroCube” nitrogen generation and storage system will be used to create the assist gases required for our laser. This gives us more control over the amount of gasses used and the main benefits will be for our clients and the environment.

Nitrogen assist gas is used by lasers for cutting thin mild steels, stainless steels and aluminium. The gas has a cooling effect which provides a superior cutting quality over other gases such as oxygen and prevents the material from melting on tight corner detail. Normally the gases would be delivered to site in the form of pressurised gas bottles or delivered into a liquid nitrogen storage facility.

Liquid nitrogen storage pipe defrosting in the setting sun after a hard days work.

In the past we have opted to have our nitrogen delivered in a liquid form for several reasons; it allows large storage of nitrogen so good prices can be obtained and it is of a very pure quality. However this storage method does have its disadvantages, such as if the tanks are not used for a prolonged period the liquid evaporates and the tanks perform a pressure dump losing large volumes of nitrogen gas. Also during refills a lot of the gas is lost back into the atmosphere.

Whilst dumping nitrogen into the atmosphere is not harmful (as 78% of the atmosphere is nitrogen) it is wasteful and there is also the emissions from vehicles delivering the gas on a frequent basis. That is one of the reasons we have opted to collect our own nitrogen on site. The cost of delivery of the liquid to our site is constantly increasing (as is the price of the liquid itself), by installing our own system we can protect our clients from these price increases. The system will also remove at least 52 deliveries a year to our site which is good news for the environment!

The project started with creating a new mezzanine floor in our fabrication shop so that the new system did not take up any valuable space.

Aluminium Mezzanine Staircase

New floor area created by a mezzanine structure.

Once the new mezzanine was completed, power isolators and nitrogen pipes were added for the system. We will also use the mezzanine floor to house a fume extraction system which will be used for a new welding bay underneath the mezzanine floor.

The first nitrogen bank is installed.

The first nitrogen bottle banks were put into place. These banks contain several bottles which store nitrogen at 250 bar of pressure. The storage will be refilled overnight and during periods of high demand will be topped up during the day. The storage tanks should provide enough nitrogen for several hours of cutting mid-range stainless steels whilst the system can replenish the nitrogen as quickly as it is used on thinner materials.

These bottles store the nitrogen at 250 bar ready for use by the laser.

The NitroCube takes compressed air from the atmosphere around it and uses special filters which only allow Nitrogen gas to pass through. This is then pressurised into the gas storage bottles. The filters are of an extremely high quality meaning the gas is very pure and will last up to 10 years before they require replacing. We’ve avoided the technology in the past as poor quality systems can produce contaminated nitrogen gas which leaves a yellow colouring on the edge of stainless steel. However we now believe that systems on todays markets can meet our standards.

Air compressor is installed which collects the air for filtration.

The nitrogen generator is lifted into position.

The system produces around 15 cubic metres of gas per hour which is enough to maintain cutting on materials up to 2mm thick, above that and our laser cutter will draw from the storage tanks which are then replenished either overnight (if no production is taking place) or during times when we are cutting thicker mild steels which uses oxygen as an assist gas.

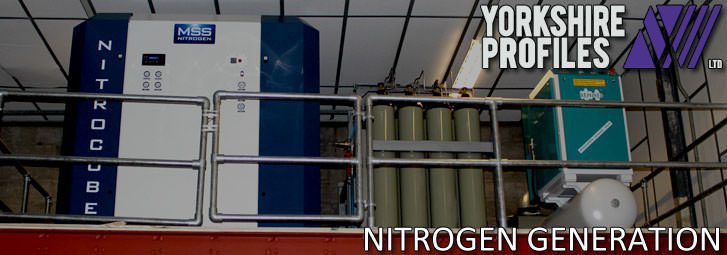

The NitroCube is a fully contained nitrogen generation system.

The system is very easy to use and enters economy mode when the storage tanks are full so there is no excess and no wastage. The system also requires a very minimal amount of maintenance.

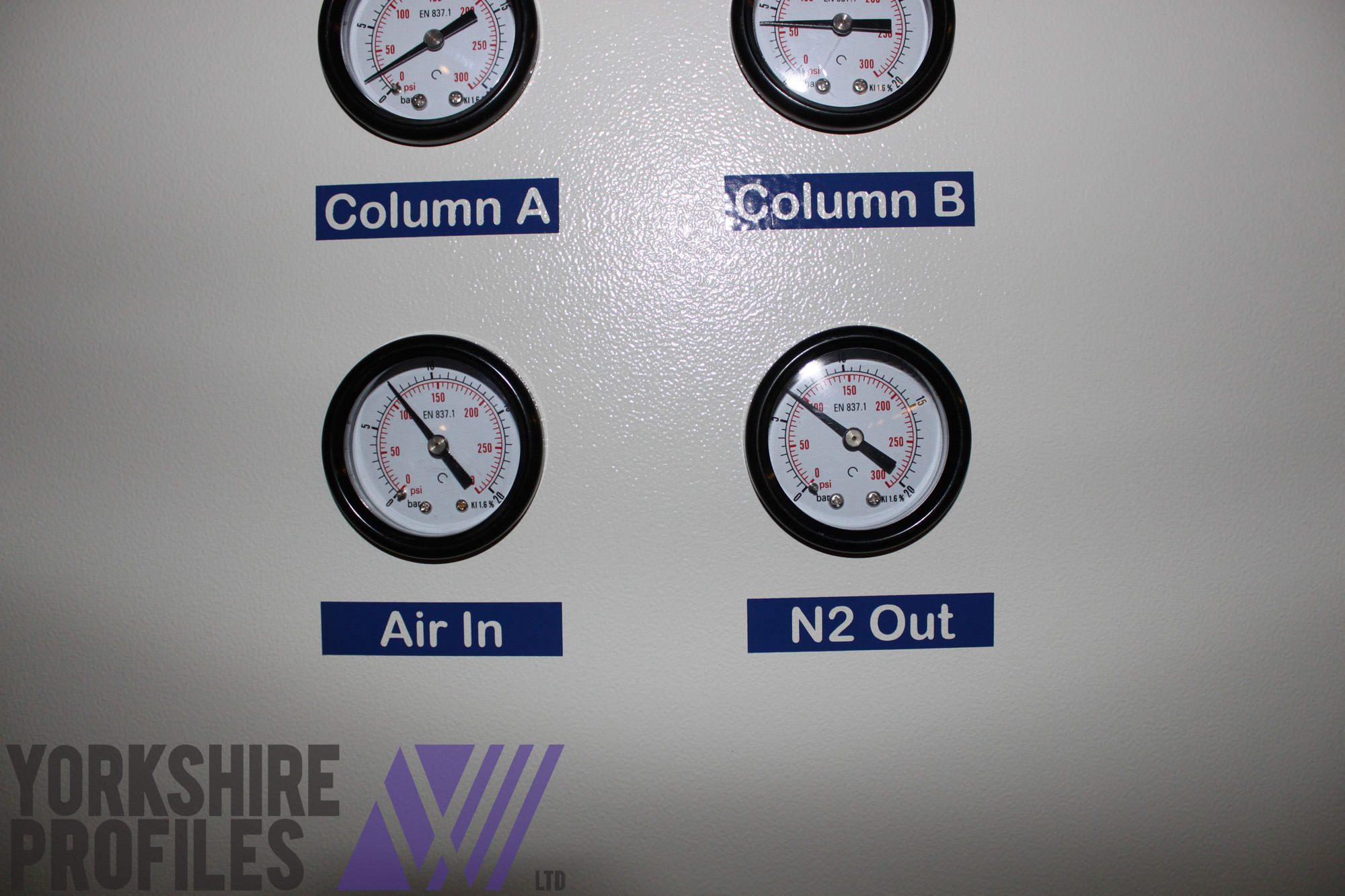

Air In = Nitrogen Out

The nitrogen system monitors the quality of the air to make sure it meets set standards.

Entire nitrogen generator and storage system in place and operational.

The latest investment shows our commitment to both our clients in terms of price and quality and to the environment by reducing waste and unnecessary deliveries where alternatives are available.