Laser Cutting Mild Steel

Mild steel is one of the most common metals we work with, and we are happy to provide a wide variety of mild steel grades. It is the most inexpensive type of steel and also the most widely used steel variant, due to its hardness, durability and its multiple applications. The most common uses of mild steel include cookware and car chassis, though due to its corrodible nature and comparatively low weight-bearing strength, only certain varieties can be used for building or structural purposes.

We use the Ventis laser cutting machine which offers fantastic quality cuts at unparalleled speeds. As a general rule, we would recommend that the mild steel doesn’t exceed 20mm in thickness for the best results, as this is the upper limit at which our laser can work effectively.

The Ventis system also offers the further benefit that the mild steel won’t succumb to to corrosion, as the laser cutting process ensures that the metal isn’t exposed to corrosive substances that have the potential to unnecessarily damage the material.

Eco-Cut System

The Ventis can also cut mild steel using the innovative ‘Eco-Cut’ system, which is both faster and more efficient than competing laser cutting machines. In order to combat the heat generated by the system during this process, we treat the mild steel with a fine spray of water and a rust inhibitor in order to keep the metal cool and prevent damage to the end product.

Cutting Mild Steel

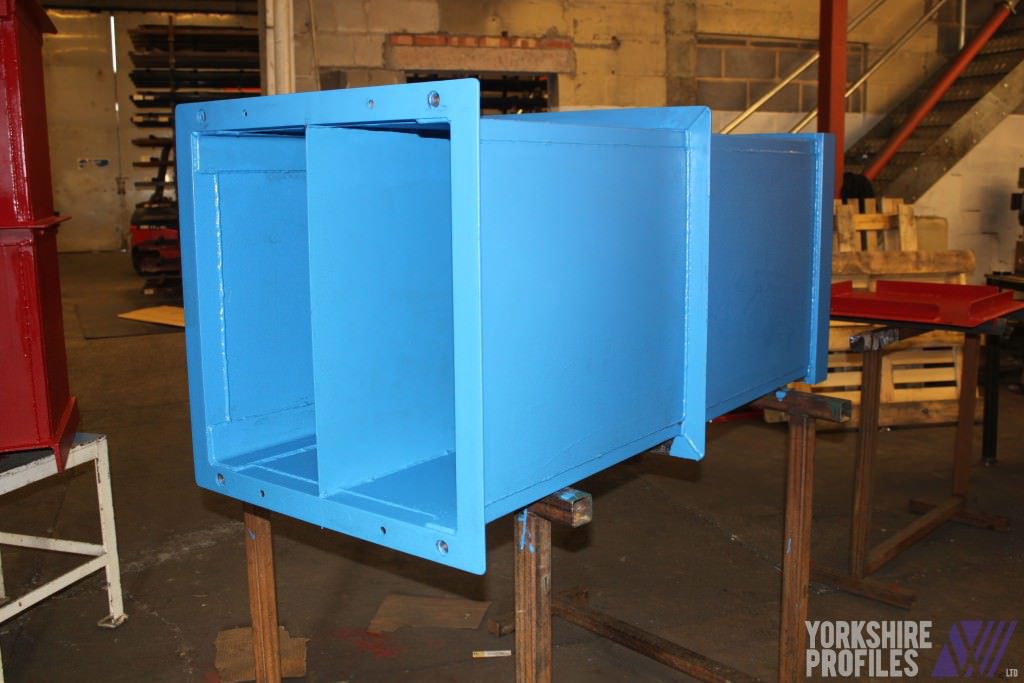

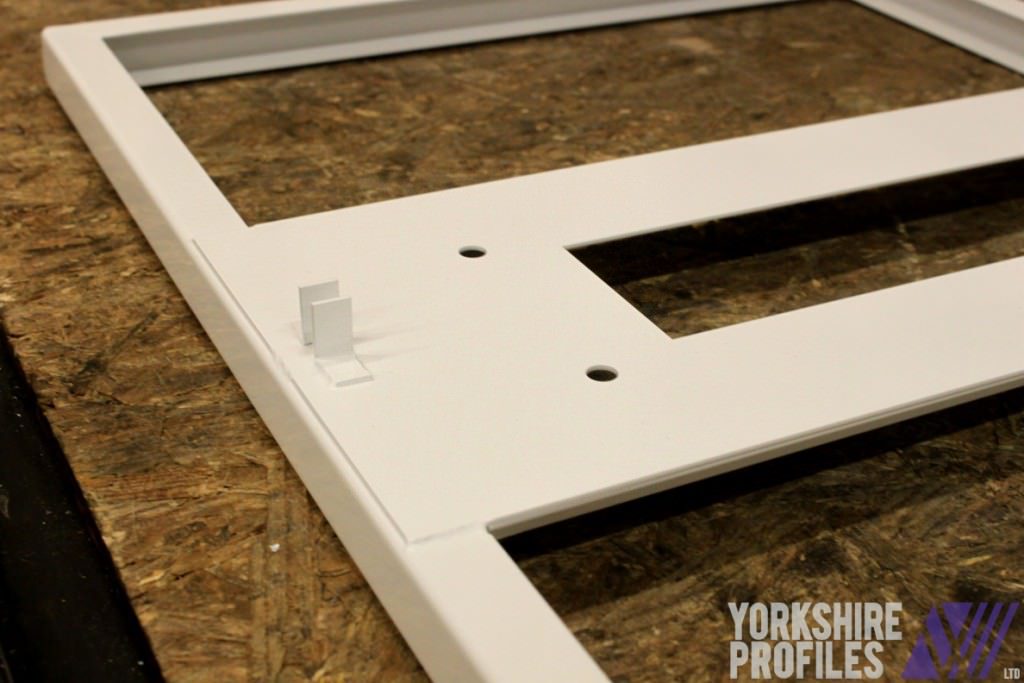

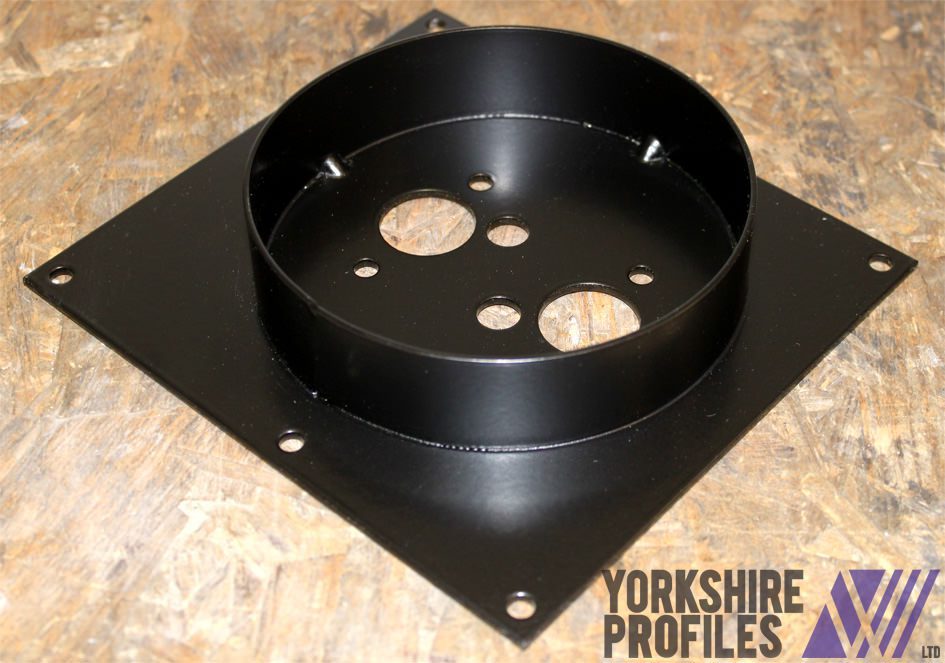

Before the mild steel is cut, there are several precautions that must be considered in order to achieve the best possible results. It is important to make sure that the mild steel has been stored correctly to prevent the onset of rust as this can greatly affect the quality of the cut, all of our mild steel stock is held indoors to ensure this is the case. Any paint or markings need to be removed from the surface to prevent interference with the cut. It’s highly recommended that all mild steel is treated or powder coated in order to prevent the metal from rusting after cutting.

This post-cutting service isn’t typically included by Yorkshire Profiles unless it is specifically requested, but it is the best way to ensure that the mild steel is thoroughly protected before it is cut. If you would like more information about how we can protect your mild steel components please see the list of our other services.

Different Types Of Steel

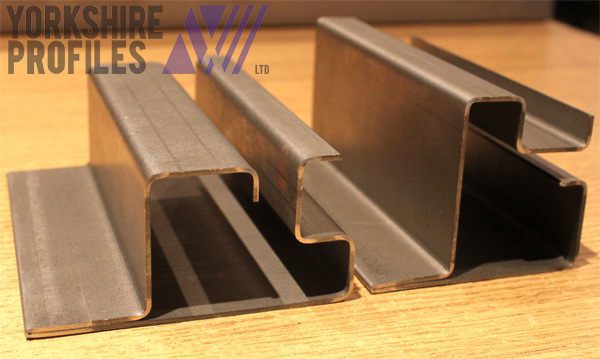

At Yorkshire Profiles, we stock several gradations of steel that are suitable for a range of purposes, and are also able to resource any other types that you may require. Some of the most popular options include:

- S275/43a

- Cold Rolled (CR – up to 3mm)

- Hot Rolled

- S335 (various levels)

- Durbar Plate

- Boiler Grade Plates

- Pre-galvanised

- Zintec

If you would like to find out more about the Ventis or any of the mild steel laser cutting services we offer, Click here to find out how to enquire.