We were recently asked to manufacture a one off small disk for a University project which was quite challenging for our laser. The main problem was that it was to be made out of thin mild steel.

The disk had to have very narrow slots put in leaving only 0.2mm of material between each slot. As with most materials, mild steel gets very hot during cutting and this small material simply melts away blending all the slots together making the part useless for its purpose. The first step to resolving the problem is to use Nitrogen gas on the part during cutting. This keeps the material cool during cutting allowing the structure to remain intact.

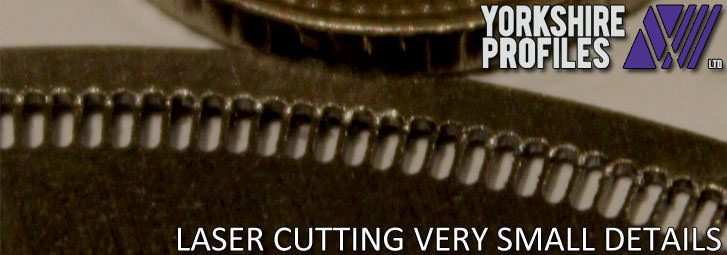

These slots are only 0.4mm wide cut in Mild Steel. [Ref: It’s a 5p coin!]

The downside to using nitrogen on this part is that it leaves small “pips” of material on the back face if it has cooled too quickly. These can be deburred carefully but the location of the “lead-in” positions have to be chosen carefully to achieve this without breaking the detail up (eg towards the outside edge of the disk).

The advantage of cutting parts such as this on a laser is the positional accuracy of the slots (they are all exactly 1 degree apart).