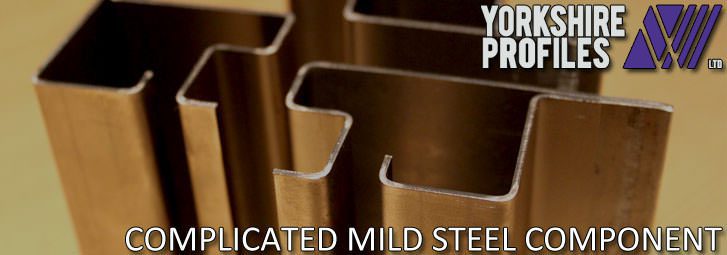

We were recently asked to try to achieve some complicated folds, I can gladly say we achieved it. The hardest part about producing such components is working out the most efficient “bend order”. This is made easier by our press brake as the console gives us a visual diagram of when a fold cannot be achieved.

If these parts are folded in the incorrect order than it becomes impossible to get the tooling which creates the metal fold into where it is required. Using our investment in “safety edge tooling” we are able to create the hem (where the metal is folded completely back on itself).

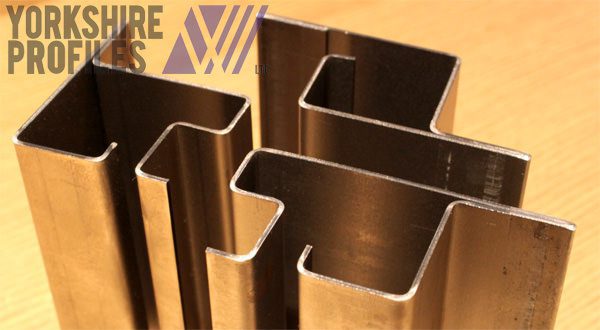

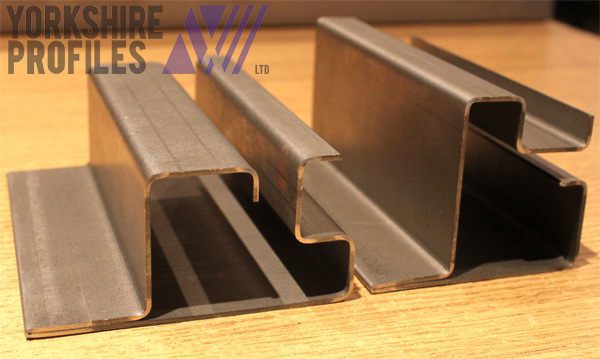

Mild steel components which were tricky to fold but achievable.

Complicated Mild Steel shapes laser cut