At Yorkshire Profiles we manufacture “hoppers” of all kind in various shapes and sizes for different industries. Quite often these have a “Square to Round” shape. This term is used even if the part is more of a rectangular shape to round, or even to an oval shape.

Mild steel “Square to Round” cut and folded

Square to rounds are usually laser cut and folded in multiple segments. The one shown above was a simple mild steel design so it could be made in two laser cut halves. They are folded using “segmented bending” which is where multiple folds are used to create a radius. The more folds which are used the smoother the end results.

Mild steel “Square to Round” cut and folded

We can use our 3D development software to correctly calculate the desired flat patterns for our laser to then etch and cut. Etching the folding lines makes it much easier and saves a lot of time in the metal fabrication stages making sure the final parts fit together correctly without requiring adjustment.

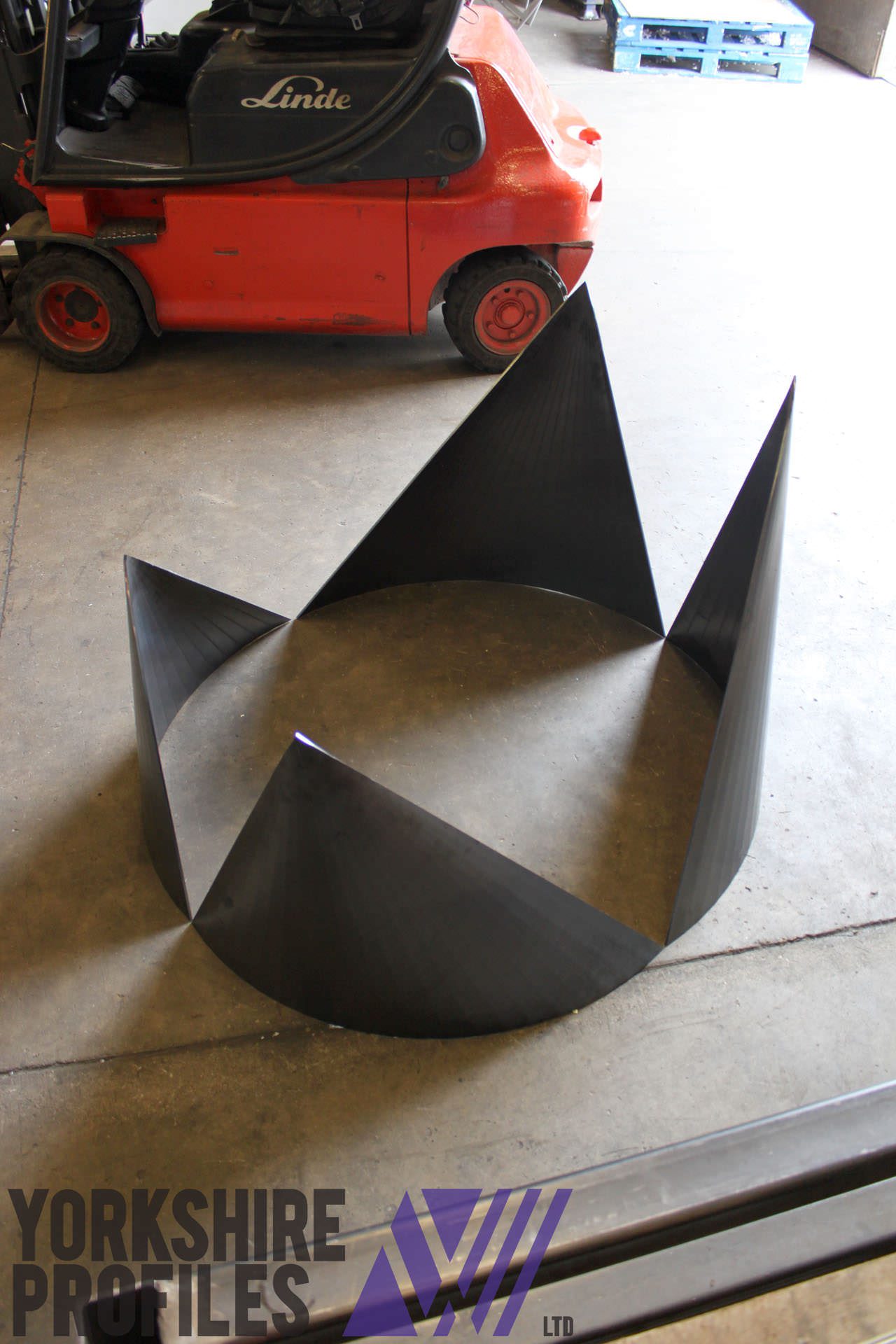

A much larger “Square to Round” which has been cut and pressed

Even if it isn’t a simple square to round our software can still calculate the correct flat patterns. This mild steel design is to fit to a rectangular steel flange which will be sat on a tapered angle, then to a round steel flange. Mild steel plates will be cut and welded to fill the triangular areas.

A special “Square to round”. This will have triangles welded into the gaps and creating a sloping angled rectangle to round.