It’s not often that a question arises which can cause chaos in the ranks at Yorkshire Profiles but during the processing of a large order an interesting issue came to light which required a bit of external advice.

The material in question is 4003 Grade Stainless Steel, also known as 3CR12. This material is supplied with a limited number of finishes compared with other grades of stainless steel. In particular we are discussing an issue regarding 1.5mm thick 3CR12 which makes the problem even more peculiar.

We recently acquired hundreds of sheets 2500mm x 1250mm of this material and began processing it immediately. It was detected that 30 sheets of the material looked completely different to all the others, as if it were a completely different metal.

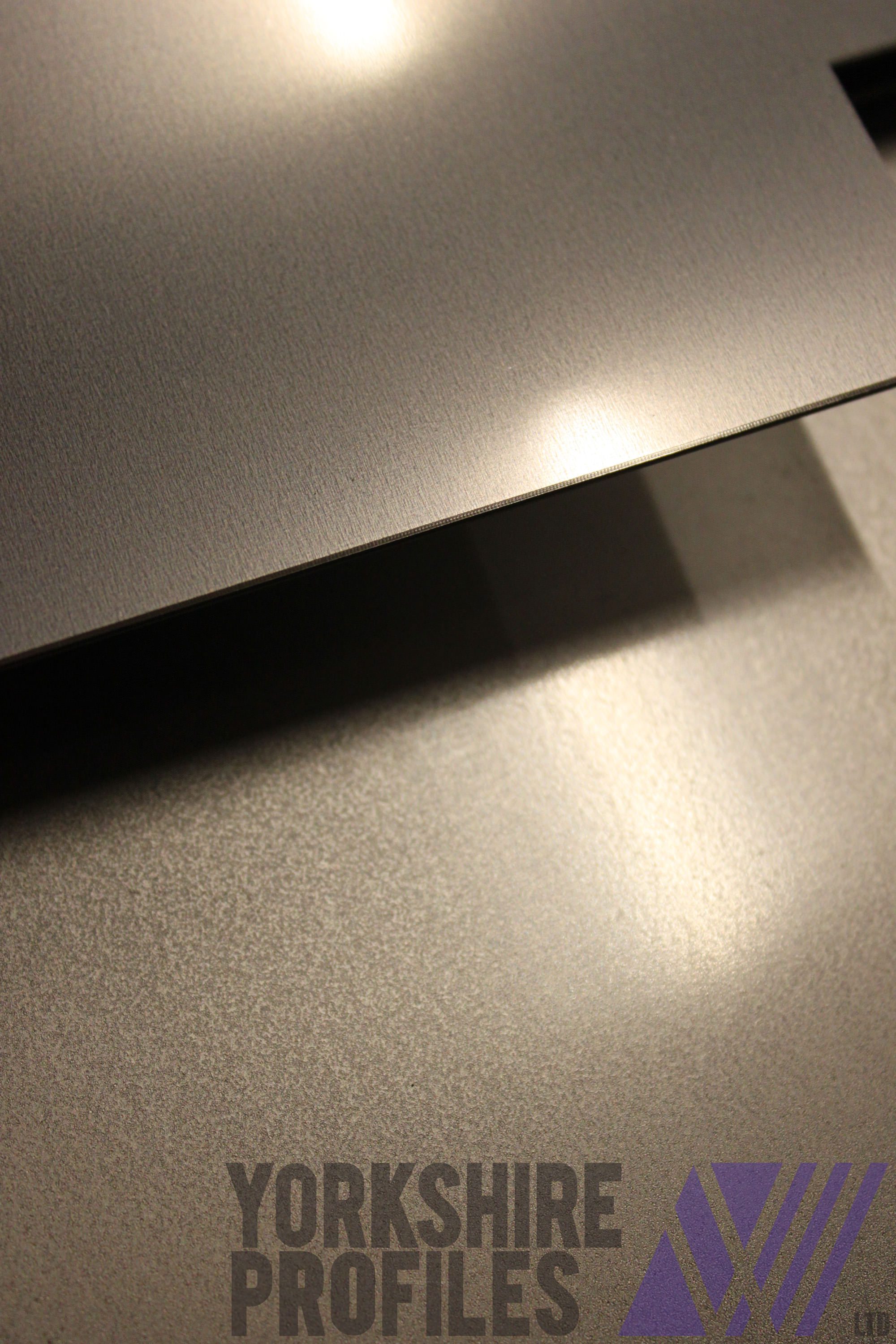

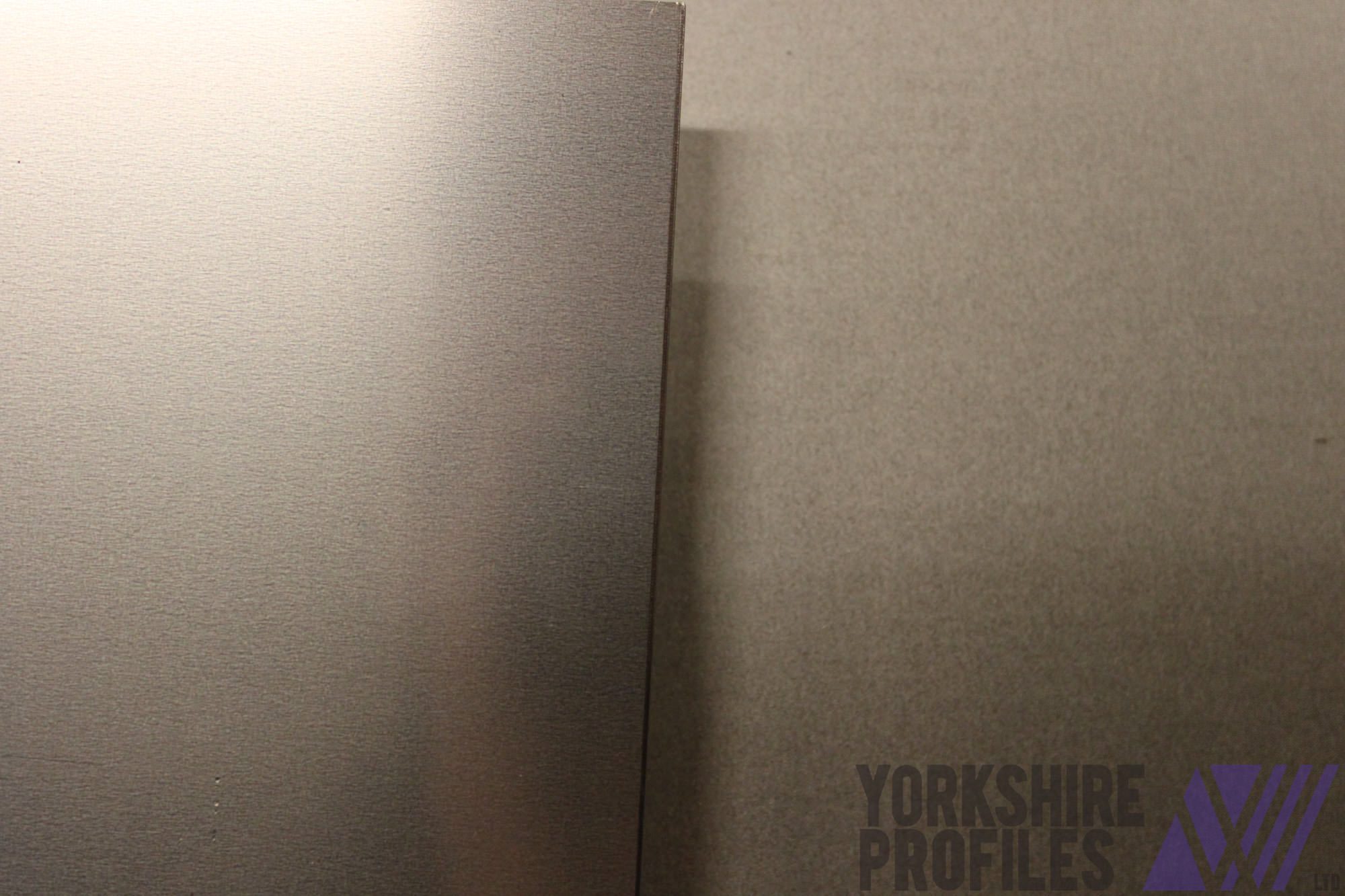

These materials have a completely different appearance despite being to the same finishing specifications.

The first step was to check our stock records including delivery notes and purchase orders, all of which confirmed the material should be the same. From experience of handling materials the top sheet looks like what we would expect for a 2B finished material (this is often the finish associated with cold rolling processes at the mill, for more information on the rolling process can be found here), and it is of our opinion that the lower sheet has more of a hot rolled or 1D appearance. To add to the confusion the lower sheet is physically printed with details stating it is “4003 CR 2B”.

The significant difference in reflectivity and colour shade can be seen here in the 4003 material (Also known as 3CR12)

We know that on a very large project where these panels can be seen and will not be coated, the significant difference in appearance of the materials will cause problems for our client. We analysed the material test certificates for both pieces of materials and both state they meet exactly the same standards required for “4003 Cold Rolled 2B”, however they were from different mills, one in Finland and one in Spain. This offered us the first solution, to replace the 30 sheets requesting they come from the original mill which will help us complete the contract on time without quality issues.

However, we still have an obligation to investigate the cause of the anomaly and to determine if this is a larger issue in the industry regarding standards or at the very least make others aware that if you order 4003 with a 2B finish, could it be completely different to your existing stock?

Both of these materials apparently meet the specification for 4003 grade stainless steel 2B finish.

The “orange peel” effect on the lower sheet is commonly seen on other stainless steels which have been hot rolled, however we are informed that 1.5mm 4003 stainless steel is only provided cold rolled so that ruled out the possibility of a mix up. We then discovered that in regards to this particular grade of stainless steel there are no set standards to the “reflectivity” or the RA value of the material.

Could this be the only explanation, that they are from different mills and a lack of a standard for a particular specification means the material can vary wildly in appearance? If so, it’s something that anyone using the material in their designs should be aware of, especially if they use multiple suppliers.

We approached the BSSA (British Stainless Steel Association) for independent advice regarding the materials and if they could offer any explanation for the differences.

These materials appear significantly different with one having a clear reflective grain, and the other more like a hot rolled appearance. Both sheets meet the same specifications for 2B.

“I agree that the surface is rougher than I would expect for a 2B surface. The problem is that there is no detailed definition of 2B in the standard. This makes it difficult to prove that it is outside spec.” states Alan, a technical advisor for the BSSA.

2B – Cold Rolled, heat treated, pickled, skin passed. Smoother than 2D which is defined as “Smooth”. Most common finish for most steel types to ensure good corrosion resistance, smoothness and flatness. Also common for further processing. Skin passing may be by tension levelling.

“There are no requirements for surface roughness values for 2B. The rough appearance of the material may be due to perhaps “overpickling” or a low amount of cold rolling of the hot rolled surface. I suspect that the mill would say that surface appearance is not usually a major issue on this grade which you can’t really argue with. Certainly, this is the first time I have come across a requirement for cosmetic appearance in 1.4003.

Given the vagueness of the definition, I guess is depends on how you interpret the word ‘smooth’.

For mill finishes, it is typical for variations in surface appearance to occur. This is why you don’t normally use mill finishes like 2B for cosmetic appearance. I am not saying that the surface roughness is acceptable. However, I think the expectations are too high for what is meant to be a ‘utility’ product.”

So to conclude this investigation, the appearance of ‘2B’ can vary with 4003 grade stainless steels and it would be unwise to have any cosmetic expectations of the raw material.